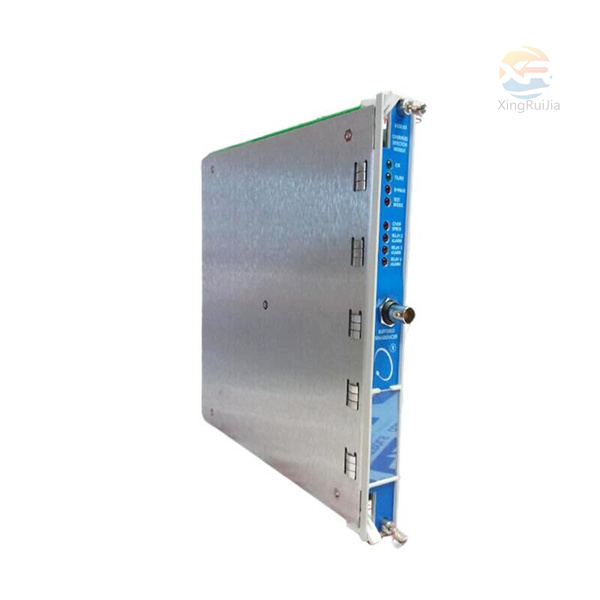

BENTLY 3500/22M

The Bently Nevada 3500/22M, also known as the Transient Data Interface (TDI) module, is a major component in industrial environments that relies on monitoring the condition of critical machinery. The following is an overview of its key features and advantages:

effect

Bridging: Connect the Bently Nevada 3500 monitoring system to compatible software applications for data collection and analysis.

Compatible software:

Bently Nevada System 1 status monitoring and diagnostic software

Bently Nevada 3500 System Configuration Software

Features:

Data collection: Collect steady-state and transient dynamic (waveform) data from the monitoring system.

Pre – and post alarm data: providing valuable insights for analyzing the root causes of mechanical problems.

Communication options:

Flexible connection and seamless network integration are achieved through Ethernet (10Base-T or 100Base-TX).

Optional 100Base-FX fiber optic Ethernet enables powerful communication in harsh industrial environments.

The USB-B port on the front panel is used for local configuration.

Status monitoring: LED indicator lights provide clear visual prompts for operational status (normal, alarm).

System reset: includes a rack reset button to clear lock alarms and perform a system restart.

Power consumption: Efficient operation, low power consumption of 10.5 watts.

Application:

Widespread industries: used in various sectors that rely on mechanical health, including power generation, oil and gas production, manufacturing, paper mills, and pulp mills.

Key equipment monitoring: Protecting turbines, generators, pumps, compressors, motors, bearings, and gearboxes in these industries.

Benefits of using Bently Nevada 3500/22M:

Enhanced reliability: By early detection of potential equipment issues, proactive maintenance is achieved to prevent unexpected downtime and production losses.

Cost savings: Reduce maintenance costs by promoting preventive maintenance practices rather than relying on passive repairs.

Improving safety: helps identify faults before mechanical failures escalate into catastrophic ones, protecting personnel and the environment.

Optimized asset management: providing valuable data for informed decision-making on mechanical health and maintenance strategies.

Reliable product quality: We cooperate with well-known industrial control brand manufacturers both domestically and internationally to ensure reliable product quality, stable performance, and low failure rate, which can meet your various needs.

Technical Support Professional: We have an experienced technical team that can provide you with professional technical support and services.

Price discount: We have established a good cooperative relationship with suppliers and can provide you with competitive prices.

Thoughtful service: We provide comprehensive pre-sales, in sales, and after-sales services, so that you have no worries.

Specifically, our advantages are reflected in the following aspects:

Rich product line: We provide various types of industrial control products, including programmable logic controllers (PLCs), human-machine interfaces (HMI), servo drives, frequency converters, etc., to meet your various needs.

Adequate inventory: We have sufficient inventory to ensure timely delivery of your orders.

Convenient logistics: We cooperate with multiple logistics companies to provide you with convenient logistics services.

Programmable Logic Controller (PLC): PLC is one of the important components in industrial control systems, used to control and monitor the production process.

Human Machine Interface (HMI): HMI is an interface for interaction between humans and machines, used to display information and parameters of the production process, and receive instructions from operators.

Servo driver: A servo driver is a device used to control the motion of a servo motor, which can control the position, speed, and torque of the motor

Variable frequency drive: A variable frequency drive is a device used to control the speed of AC motors, which can achieve stepless speed regulation and energy conservation.

Other industrial control products: including robots, sensors, instruments, etc

1)100% full New! – Original Factory Seal !

2)Warranty: 12 months!

3)Package: Original packing with cartons.

4)Delivery time: Shipped in 3 days after payment

5)Payment Terms: TT, Pay pal & Western Union

6)DHL/TNT/UPS/EMS/Fedex

Brand: FOXBORO

Item NO.: FBM03

Payment: T/T, Western Union, Paypal

Product Origin: American

Shipping Port: XIAMEN, CHINA

Lead Time: IN STOCK

Condition: 100% full New !Original Factory Seal !