Digitization is a hot topic in today’s industrial field. Group companies with hundreds of thousands of people and private enterprises with more than a dozen people are talking about digitization.

Digitization has been closely linked with intelligent manufacturing, flexible production, improving productivity, improving production efficiency, cloud services, big data, etc. to improve the competitiveness of enterprises through digitization.

People engaged in different jobs may have different answers to the understanding of digitization. But all the answers have one thing in common, that is, digitization is to integrate the virtual world and the real world through digital technology, to help people solve the difficulties and challenges they are or will face, to meet the actual needs of market development, to bring business growth, and to lead the market. It is grounded, not a virtual and empty “shelf”.

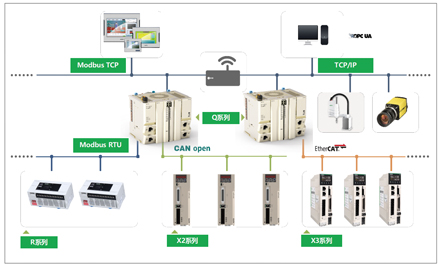

General motion control is more related to production machinery and equipment, focusing on the running speed, working accuracy, dynamic response, synchronization and coordination of the machine. It can be understood that the digitization of general motion control is to use digital means or big data analysis to help motion control solve market pain points. Therefore, shortening product launch time, meeting equipment flexible production, improving production efficiency and realizing pre maintenance are the typical characteristics of digitization of general motion control.

Next, from the dimension of motion control, analyze and dissect the digitization of general motion control. From the beginning of design to stable operation, a mechanical equipment is roughly divided into five parts from the dimension of motion control: system design and selection, equipment programming, on-site commissioning, equipment operation and equipment maintenance.

In the whole process, the digital application of general motion control is mainly reflected in the following three aspects:

01 virtual debugging

The NX MCD electromechanical simulation software of Siemens is used to select the electrical type of the equipment in the mechanical design stage of the equipment; Before the equipment is installed, the simulated movement of the equipment can be carried out.

In the system design and selection stage, based on simulation, appropriate motors, drivers and controllers can be selected to make the system selection more accurate.

In the programming and testing stage, plcsim advanced and simit of TIA portal can not only simulate the logic control program of the equipment, but also simulate complex motion trajectories, such as electronic cam curve, etc. The program is more in-depth and targeted. At the same time, it also has the mechanical error correction ability of the equipment, which saves a lot of time for on-site debugging and improves the debugging efficiency. With the help of the digital simulation software of drivesim drive system launched by Siemens, the simulation of drive technology can also be realized, such as speed loop, current loop, etc.

Siemens has complete digital virtual debugging and selection tools: TIA portal plcsim advanced, NX MCD, simit, drivesim, sizer, TIA selection tool, etc.

02 drive one key debugging

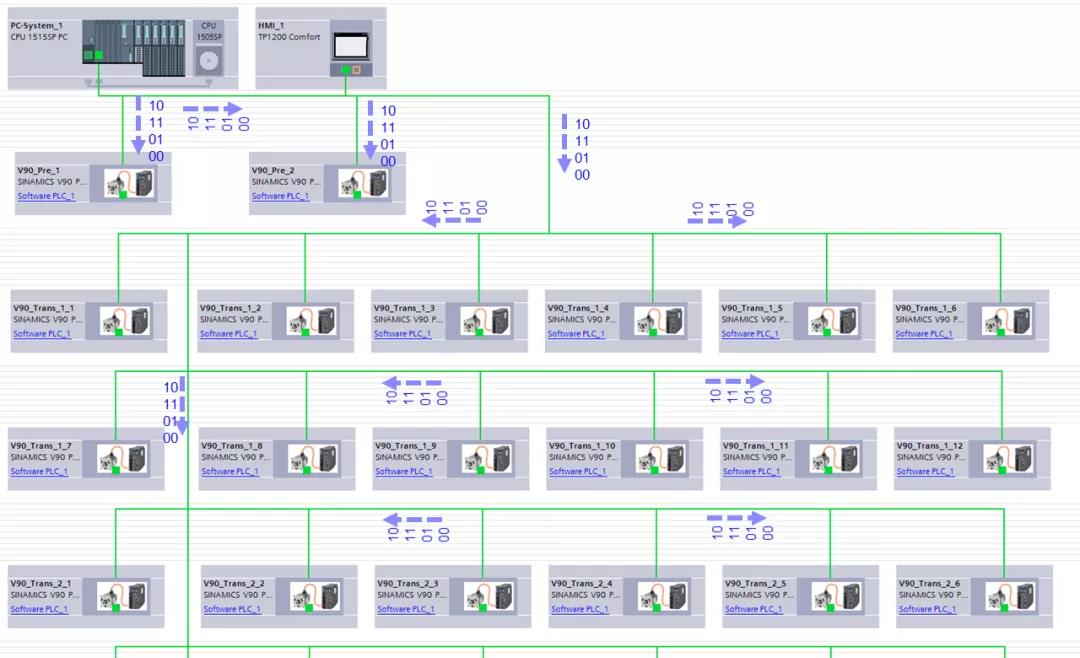

All drives on the network can be quickly debugged directly through the upper controller, and there is no need to debug each drive separately, which is mainly reflected in the following aspects:

Collect and analyze the real-time data of the driver, continuously optimize the key characteristic data, make the driving system run in the best state, and finally form the expert system of driver parameters.

One click debugging is based on letting professionals do professional things and using digital means to make the debugging of the drive system faster and more professional.

The application technology team of Siemens general motion control department has developed the “one click debugging” function package for SINAMICS V90 and SINAMICS S210, which will be gradually improved and extended to SINAMICS G120 driver in the future.

03 operation data analysis and pre maintenance of motion control system

Real time acquisition of motion control system data, big data analysis and formulation of corresponding strategies have the following characteristics:

Quickly collect data, which can accurately reflect the state of the equipment in the whole movement process, including acceleration, uniform speed, deceleration, etc

Combined with the characteristics of industry, application, drive system and machinery, big data analysis is carried out by using edge technology, and three areas of equipment work are calculated: work area, early warning area and alarm area. Realize data visualization through it technology

According to the working characteristics of the three areas, the optimization and pre maintenance of equipment operation are realized

Because the data analysis will involve the load curve of driver and motor, sometimes it is difficult for manufacturers to provide detailed curve data. The application technology team of Siemens General Motion Control Department reserves a large amount of data and algorithms for specific industry equipment and driver systems according to the curve data of Siemens drivers and motors and years of motion control experience, which can meet specific applications and will continue to improve more industries and applications in the future

With the deepening of intelligent manufacturing, digitization will play a more and more important role in the transformation of China’s manufacturing industry. At the same time, digital technology puts forward higher requirements for motion control engineers.

Post time: Nov-27-2021