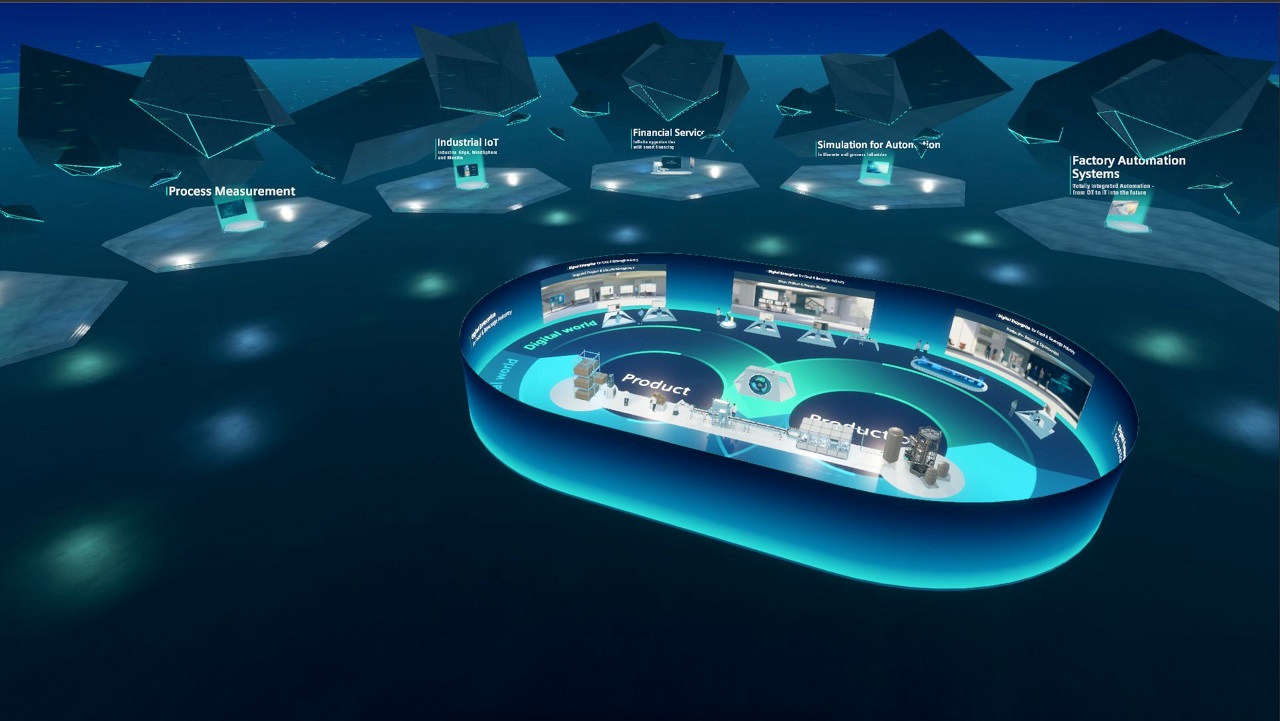

Siemens takes “unlimited opportunities for data empowerment” as the theme, Participated in the 2021 Nuremberg electrical automation system and Components Exhibition online (SPS), a comprehensive display of the latest products, services and solutions in its digital enterprise product portfolio, enabling manufacturing and process industries to better respond to rapidly changing market needs and external environment. Siemens has achieved this goal by integrating the real and digital world. Therefore, industrial enterprises can achieve flexibility by taking advantage of automation, electrification and digitization And sustainable production, while deeply mining the value of data. The innovations and highlights exhibited by Siemens at SPS include the connection between drive and Siemens Industrial edge platform, industrial 5g router installed in cabinet, and drive simulation software solution. In addition, Siemens has also launched new spare parts management services and solutions, B2B market for industrial enterprises, and ecosystem based carbon emission data exchange solutions.

In the industrial fringe, Siemens has also established a cross manufacturer independent Mall for its industry customers. The mall carries the trading mechanism of Siemens Industrial edge: an innovative IT platform that enables the scalable deployment of IT technology in the production workshop. Customers will benefit from various software components provided by many suppliers and manufacturers and integrate these components into their manufacturing processes in a standardized manner. At present, various products in the mall have covered projects such as connectivity, data storage, visualization and analysis, machine monitoring, energy and asset management. As an open software platform, industrial edge technology has become the basis of creating edge computing ecosystem.

The hardware product portfolio of industrial edge technology is also developing continuously. Industrial grade SIMATIC ipc227e and 427e are ideal platforms for industrial edge and artificial intelligence (AI) applications.

In addition, in the field of drive technology, Siemens explained the importance of further integration of drive technology and digital technology, and launched drivesimbasic software solution to simulate, adjust and optimize the drive system and its performance in machines and factories. This innovative solution designed by Siemens can ensure that machine and equipment manufacturers can quickly and easily implement drive technology simulation, so as to speed up their development process. Moreover, with the help of analyze mydrives edge, the drive system can now be connected to the industrial edge platform to realize real-time data analysis.

Industrial communication and network, identification and positioning technology constitute the basis of industrial digitization. Siemens, through its SCALANCE mum856-1, demonstrated the industrial 5g router installed in its cabinet in the online activity for the first time. The device can connect local industrial applications to public 5g 4G (LTE) and 3G (UMTS) mobile wireless networks. With the help of public 5g networks, the router will have extremely high data rate and flexibility, and can be used for remote monitoring and maintenance of factories, machines, control components and other industrial equipment. In addition, the equipment can also be integrated into dedicated 5g networks. Therefore, SCALANCE mum856-1 has the ability to support future oriented applications (such as mobile robots in manufacturing, automated guided vehicles in logistics, and augmented reality applications for service technicians).

Operators of large enterprise networks are increasingly facing the challenge of remote intervention in production while following OT and it security standards. In order to ensure that the integration of OT and it will not make the communication network face greater potential threats, “defense in depth” ot security concept has been extended to “zero trust” it security concept. At present, Siemens is working with cloud security technology leader zscaler Co., Ltd. (NASDAQ: ZS) to develop security solutions to ensure that customers can remotely and safely access the production network at their workplace (office or remote location) (OT). These new functions not only need to continue to meet users’ production requirements for availability and real-time capabilities, but also give users the ability to remotely manage, control quality and diagnose and analyze remote problems. To achieve this, the cloud based remote access service zscaler private accesstm The application connector of (zpatm) can be installed on the docker container of Siemens SCALANCE LPE local processing platform, so as to create an access solution for manufacturers.

Post time: Dec-18-2021