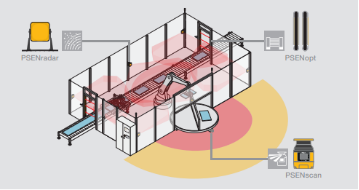

Different security sensors are suitable for different scenarios. Only by selecting the appropriate safety sensor according to the actual application can it give full play to its efficiency and protect the safety of personnel and equipment.

General guidelines for the selection of safety sensors

If the application environment of the safety sensor is relatively clean and the optical method can be applied, the safety scanner or safety light curtain is the right choice.

For some scenes with harsh application environment, such as pollution and more dust, it is recommended to use safety radar. For the environment with extreme temperature difference and poor weather conditions, safety radar is also a very good choice.

Static or dynamic application?

The security light curtain / grating is suitable for intrusion object monitoring on the static two-dimensional plane, while the security scanner can be used for protection and dynamic navigation mobile applications, such as AGV protection. The security protection provided by the security scanner also covers the static application category. Its key word is access control or preventing intrusion from the rear of the equipment. In fact, if the protection target is to detect objects in three-dimensional space, then security radar is also a good choice. This also shows once again that for a single case, there can be multiple criteria to determine which type of protection technology can and should be used.

Safety light curtain / grating is mainly used in the implementation of barrier free safety solutions. When the production process is not 100% automatic mode, the operator needs to intervene through the open entry point. If the requirement is high resolution and short reaction time, the safety light curtain / grating is the right choice. However, if the whole area needs to be protected in a sub region, the security scanner is more appropriate, because the scanner technology has higher accuracy in the edge definition of the protected area. Scanners can detect objects of any material, while security radar sensors are sensitive to specific objects, such as water, metal and moving objects

When to use which safety sensor depends on the specific application, but no matter what type of production task, appropriate protection can effectively reduce risks and improve production efficiency, which is beyond doubt.

Post time: Feb-08-2022